Client is a leading Water Treatment company that has developed a well-known reputation for designing, building, installing and servicing the finest water treatment systems available for custom homes and commercial installations. Their products and services solve water quality problems and concerns. This is accomplished by offering high quality (Inventory Management Process) water treatment equipment through a technically competent sales staff and insuring proper system operation through our highly trained service department.

Inventory Management Process

Business Need

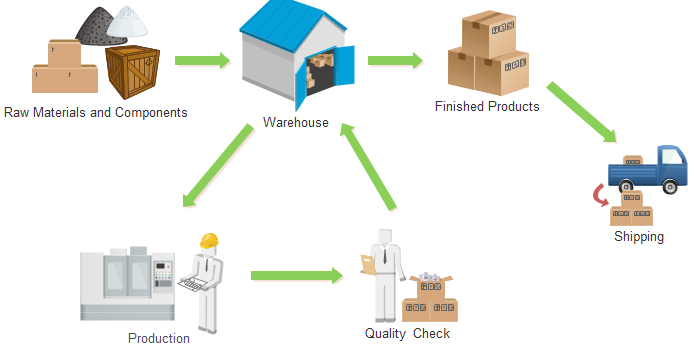

- Client stocks 2000+ inventory parts in their warehouse that are issued for various service orders to on-site jobs or service vehicles. The unused parts are returned back to the warehouse. This workflow was not managed and tracked well and lacked formalization.

- Client had a huge challenge managing this process and accounting for stock inventory that tied closely into the re-ordering process. As a result client did not had a good understanding of how much capital was tied into the inventory and often re-ordering was parts was based on gut feel estimates.

Our Solution

- We worked with the company management to understand the workflow and provide advise on simplifying the workflows. Thereafter we instituted a formal paper manual process to track inventory exit and entry in the warehouse. In addition a monthly inventory physical count process was implemented.

- Great Plains Software was configured and integrated with accounting modules to thereafter ensure that daily movement fo parts is tracked and accounting for in the General Ledger. Thereafter parts were ordered to appropriate vendor on daily / weekly basis.

- Our virtual team also took the daily scanned feed of inventory tracking papers and updated them in Great Plains with 24 hour turnaround thus keeping the system updated.

Benefit & Value

- The revised workflow and process enabled client to do Just-In-Time (JIT) management of inventory thus allowing better management of cash-flows and freeing up un-necessary capital tied up on inventory.

- Client was able to optimize warehouse – eliminate parts in the warehouse that were obsolete by either returning back to vendors or re-selling them or using them in jobs that would permit use.

- Accurate maintenance of inventory in the warehouse while clear understanding of locations where inventory resides thus simplifying the time required for warehouse manager and technicians to

- Better team morale and trust in the management’s ability manage customer orders in timely manner.

- Better trust and relations with vendors who supply parts as the new process allowed better forecasting of needs.